We are here to assist you

For more information, please leave a message and our team will contact you as soon as possible.

For more information, please leave a message and our team will contact you as soon as possible.

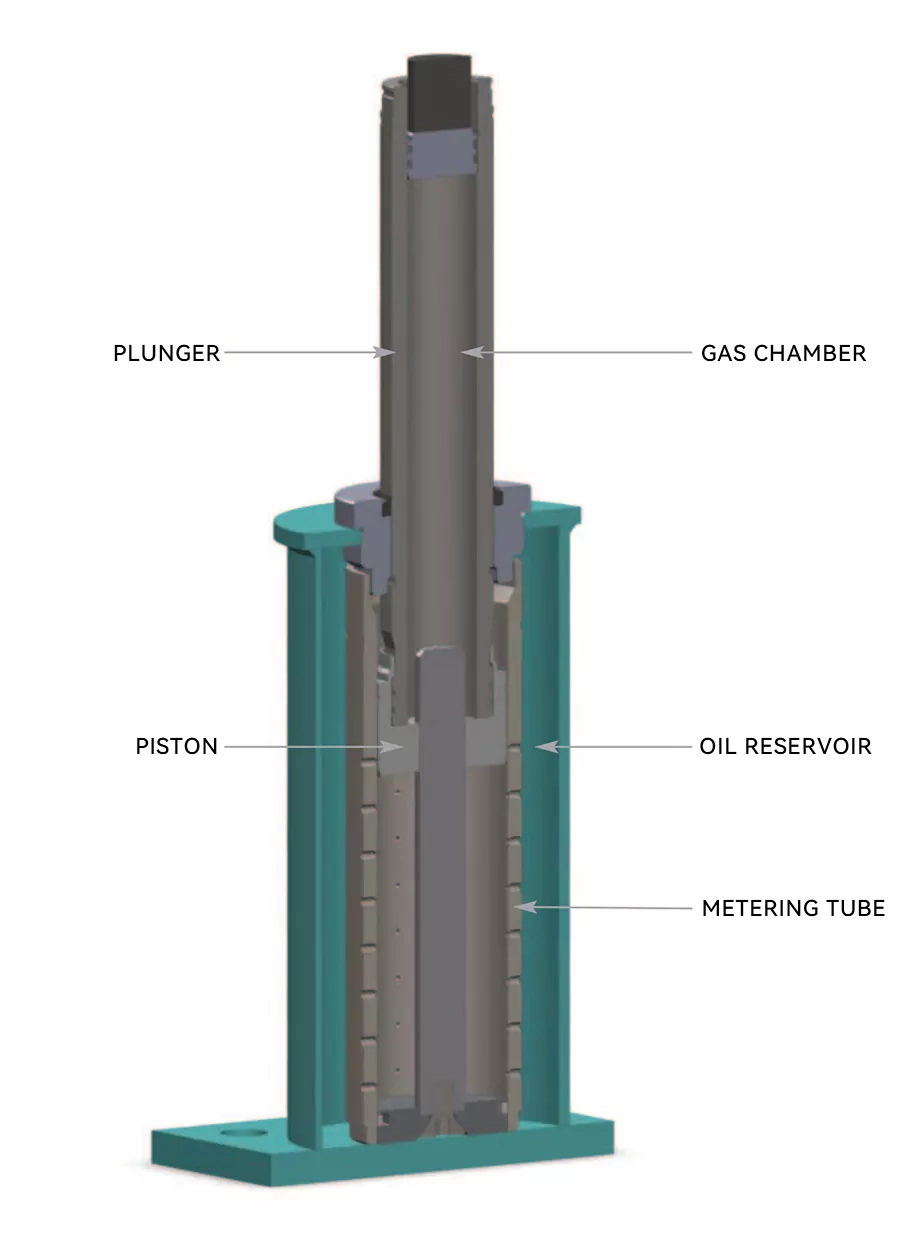

The illustration shows the robust construction of the Oleo elevator hydraulic buffer unit.

On impact the plunger is forced down around the gas rod and through the metering tube displacing oil through holes, thereby decelerating the impact mass. Following impact the gas hydraulic buffer returns to its full height using a unique method of moving the gas within the chamber.

The buffers performance on impact relies solely on oil displacement, the gas spring serves only to re-extend the plunger When the plunger is forced into the cylinder rapidly the oil displaced by the plunger has to pass through the metering holes at very high velocity. This raises the pressure in the oil chamber to a level which optimises the closure force of the unit.

This very useful feature is accomplished by Oleo’s innovative metering designs which progressively alter the flow area as the unit closes. The actual metering designs are precisely calculated to provide the best possible protection.

The Oleo hydraulic unit therefore possesses the unique feature that its characteristics change according to operational needs. The majority of the impact energy is absorbed within the unit and the already low recoil force is damped by the reverse flow of oil, leaving very little energy and recoil force to be returned to the impacting vehicle.

For more information, please leave a message and our team will contact you as soon as possible.